How drives save energy

Energy is defined as the capacity of a physical system to perform work. In essence, energy is a fundamental quantity that can exist in a range of different forms, most notably heat, light , kinetic, electrical and potential energy. Energy cannot be created or destroyed, but can transition from one form to another. For example, the kinetic (movement) energy from a clap can become sound energy when hands make contact with one another.

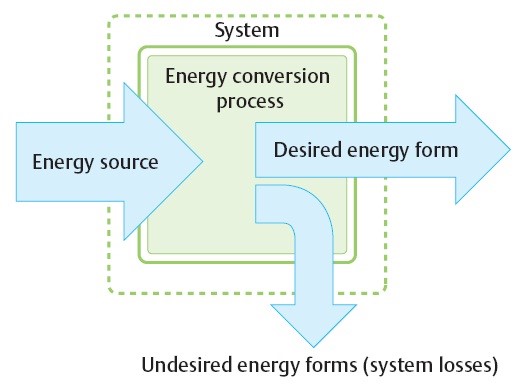

Energy efficiency refers to the proportion of useful energy that can be converted from aEnergy Efficiency = Minimizing Losses

source into a desired form. In any energy transfer, the output ‘desired energy form’ (if measured in joules) is always less than the energy source in joules because during the conversion some energy is expended in different forms during the conversion.

Stand alone motors cannot alter their speed. They are designed to rotate at a set speed based on the number of magnetic poles built into them and the supply voltage and frequency applied to them. Even for fixed speed systems, it may be difficult to find a motor that rotates at the correct speed for its designated application. Extra parts may need to be purchased such as:

- Gears

- Process controls (dampers(

- AC drives

All motors have a nameplate that indicates how fast they will rotate, in revs per minute (rpm), at a given voltage frequency and load current. AC drives are devices designed to provide effective speed control of AC motors by manipulating voltage and frequency, and therefore the magnetic flux inside the motor circuit.

Controlling the speed of a motor using modern AC drives not only provides users with much improved process control, but can also reduce wear on machines, increase power factor and provide large energy savings.

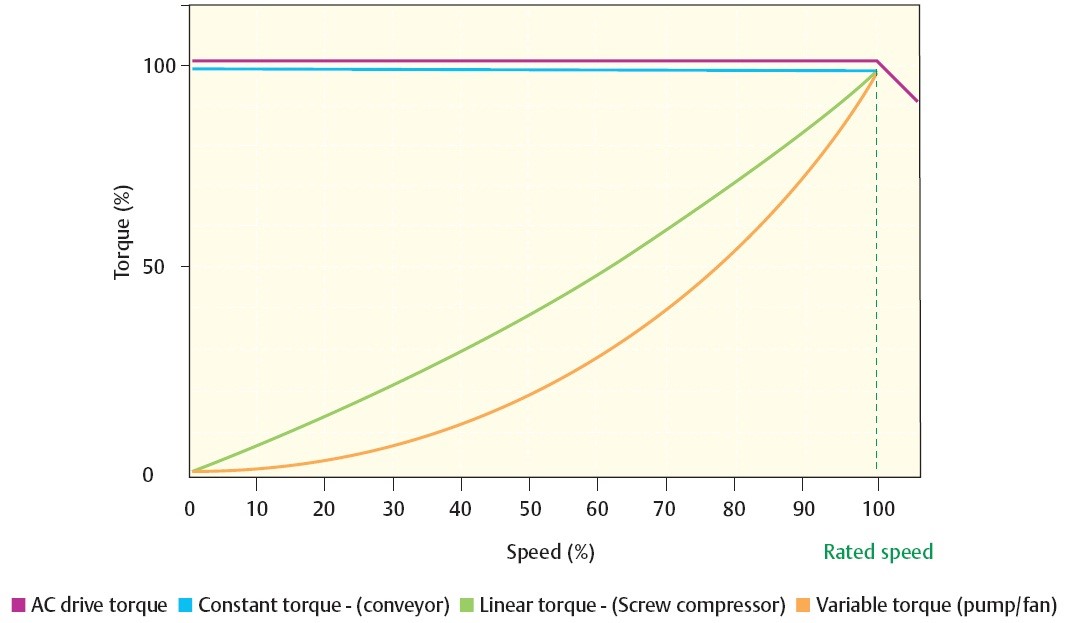

Most application load profiles can be grouped into the following torque categories:

- Constant torque load – such as conveyors, often require a starting torque close to the rated torque of the motor and show only small changes as they approach rated speed.

- Linear torque Loads – such as screw compressors, have a more linear torque requirement that increases proportionately with speed.

- Variable torque loads – such as pumps and fans have torque requirements that increase in proportion to the square of the speed and reach 100% torque just below rated speed.

Application Load Types

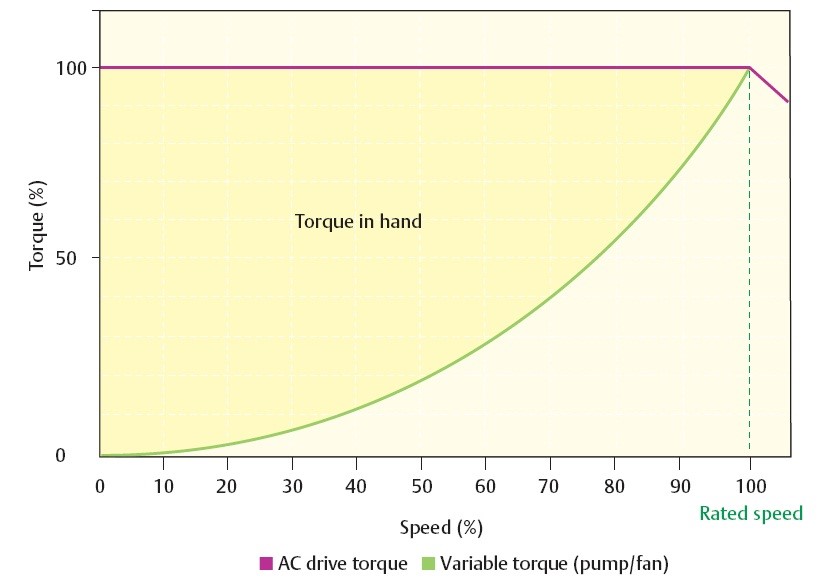

Using speed control, the most significant savings can be made on applications that obey a variable torque requirement, such as pumps and fans. Because of the cube law relationship between speed and power, simply reducing a fan speed by 20% can yield a power saving of almost 50%.

Reducing the speed of the motor is usually the first step in reducing the energy bills as small changes in speed can reap large energy savings. AC drives provide the means to this; but can they also do more?

Square law fluxing

Square law fluxing, sometimes called ‘fan fluxing’ or ‘square law’, is a feature within Control Techniques AC drives which can provide further energy savings when controlling variable torque loads such as pumps and fans.

Varying the speed of variable torque loads can yield power savings proportional to the speed reduction cubed. This is because power is a product of torque and speed, with variable torque loads having torque requirements that increase in proportion to the square of the speed. In linear voltage-frequency mode, AC drives can provide 100% torque up to rated motor speed, meaning that, in variable torque applications, there is always plenty of torque capability ‘in hand’ below rated speed.

Square law mode manipulates the linear voltage to frequency relationship so that the torque capability, and hence flux, in the stator windings of the motor is reduced, reducing losses.

Dynamic V to F mode

Control Techniques drives include dynamic V to F mode which is intended for applications where power loss in the motor should be kept to a minimum under low load conditions. In this mode the drive will vary the voltage to frequency characteristic it applies to the motor depending on load level, such that at light load levels the voltage on the motor is reduced for a given frequency. This reduces the magnetizing (or flux producing) current which in turn reduces losses in the motor.

PID control

As previously discussed, AC drives can significantly reduce energy consumption by varying the speed of the motor to precisely match the effort required for the application. To vary the speed of the motor dynamically, a closed-loop regulator (or control loop) that takes into account the measured output of a process is required. Common applications where this is used include pressure, level and temperature control. The most common method of regulation is the PID (Proportional-Integral-Derivative) control loop. All Control Techniques drives have either single or multiple PID loops integrated within the product.

Active Front End Systems (AFE)

The input stage of a non-regenerative AC drive is usually an uncontrolled diode rectifier, therefore power cannot be fed back onto the AC mains supply and excess energy in the system is ‘dumped’ in a power resistor and therefore converted to heat. AFE systems use a controlled IGBT rectifier bridge which enables energy to flow bi-directionally to and from the mechanical system and the AC supply. This provides far greater efficiency levels than standard AC drives in applications where electrical braking of the mechanical system would result in significant amounts of energy being wasted within the braking resistor.

Control Techniques standard Unidrive SP AC drive modules can be connected as an AFE system. Two drives are used, one to control the flow of energy from the line supply to the DC bus and the other to control the flow of energy from the DC bus to the motor. The main advantages of an AC regen system are:

- Energy saving

- The input current waveform is sinusoidal

- The input current has a near unity power factor

- Power factor correction can be implemented

Common DC bus systems

DC bus systems offer an another approach to reduce running costs by circulating energy between braking and motoring drives. An application example where this is particularly effective is systems where material is unwound and then re-wound. In this application it is important to maintain tension in the material, to achieve this the unwinder is constantly braking and the winder is constantly motoring. In a perfect system, the net energy required is just enough to supply the system losses.

Combining an AFE with a common DC bus systems offers the maximum power system flexibility, allowing energy to flow between drives and bi-directionally with the line supply. It is common in these applications for a single AFE unit to be used with many DC bus connected drives, the AFE is rated for the requirements of the system.

Calculating the Return on Investment (ROI) for energy saving applications

Control Techniques energy optimising software helps you analyse the energy usage for different applications and calculate cost savings using AC drives. The main features of the software are:

- Estimation of energy usage using AC drives for fan and pump applications

- Comparison of energy consumption between AC drives and conventional control methods

- Display of energy cost, savings and payback data

- Graphical representation of flow versus cost, hours and time

- Customised client report facility including view, print, e-mail and file export functions

- Built in engineering calculator for horse power, torque, AC motors, Ohm’s Law and AC power circuit calculations.